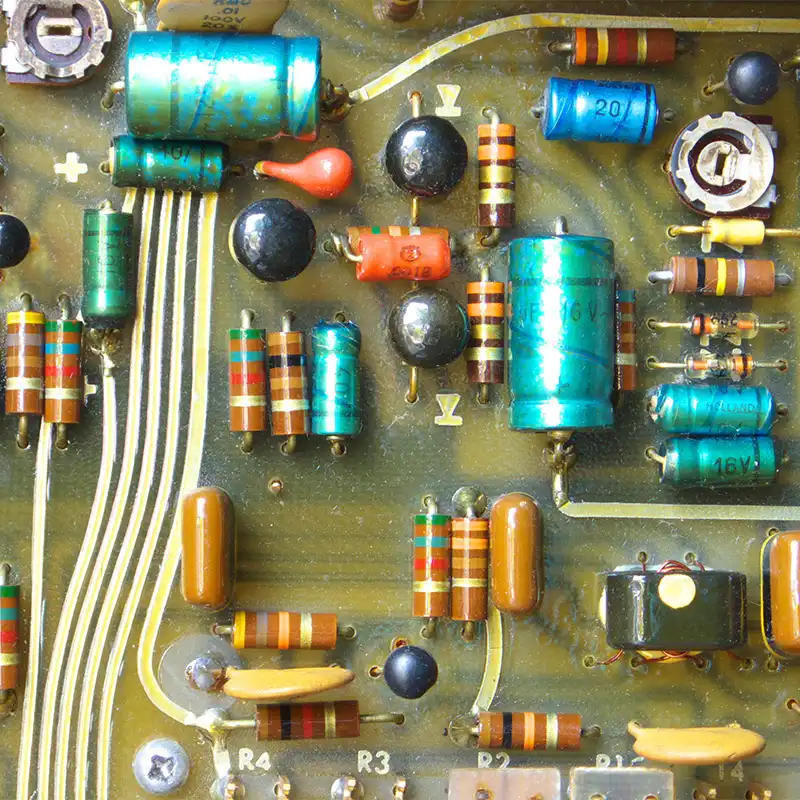

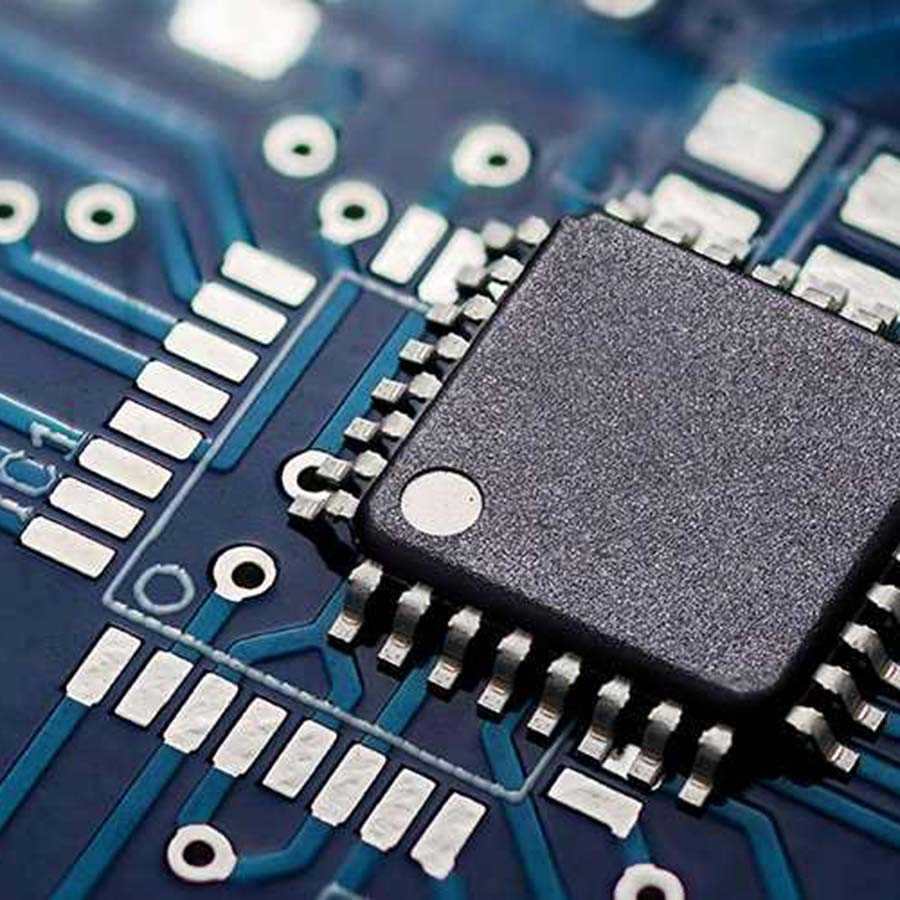

The ever-evolving field of PCB design and manufacturing has historically relied on labor-intensive manual methods, such as the meticulous arrangement of through-hole circuit boards on light tables with black tape and sticky dots.

The introduction of early CAD systems revolutionized this process, greatly enhancing efficiency - but with the continuous advancement of technology, especially the emergence of small, fine-pitch surface mount components, more adaptable systems and manufacturing processes have become essential.

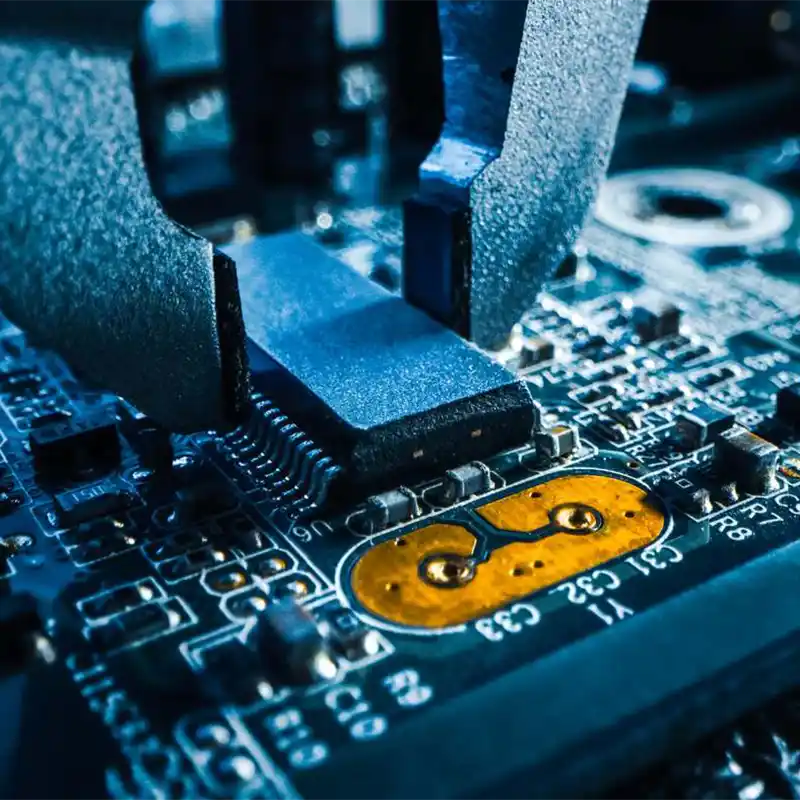

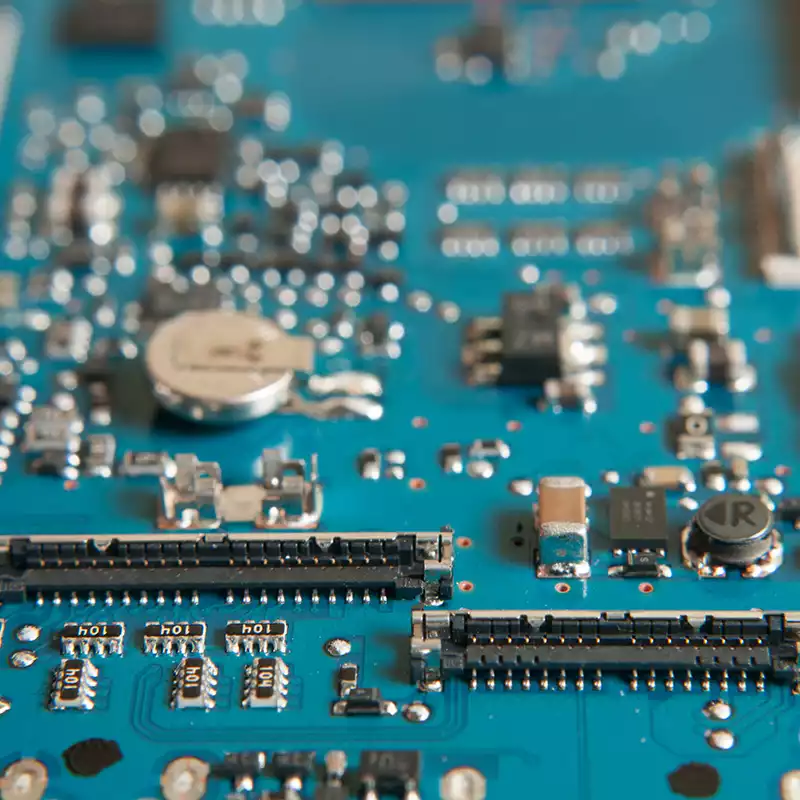

Printed circuit boards (PCBs) are the unsung heroes behind the electronic devices we rely on daily. These delicate pieces of technology, comprising various electronic components and intricate pathways, are susceptible to a wide range of environmental hazards. Protecting them is paramount to ensure the longevity and reliability of electronic devices. Among the methods used for this purpose, potting stands out as a robust and effective approach. In this article, we will delve deeper into potting and its significance as a great way to protect circuit boards.

In an era where electronic devices permeate every facet of our lives, ensuring their functionality under all circumstances is essential. However, there exists a category of environments and industries (like military and aerospace) where electronics face substantial challenges—harsh and demanding conditions like extreme temperatures, humidity, corrosive chemicals, and mechanical stress. To safeguard electronic components and circuits from such unforgiving surroundings, the role of conformal coatings is paramount.

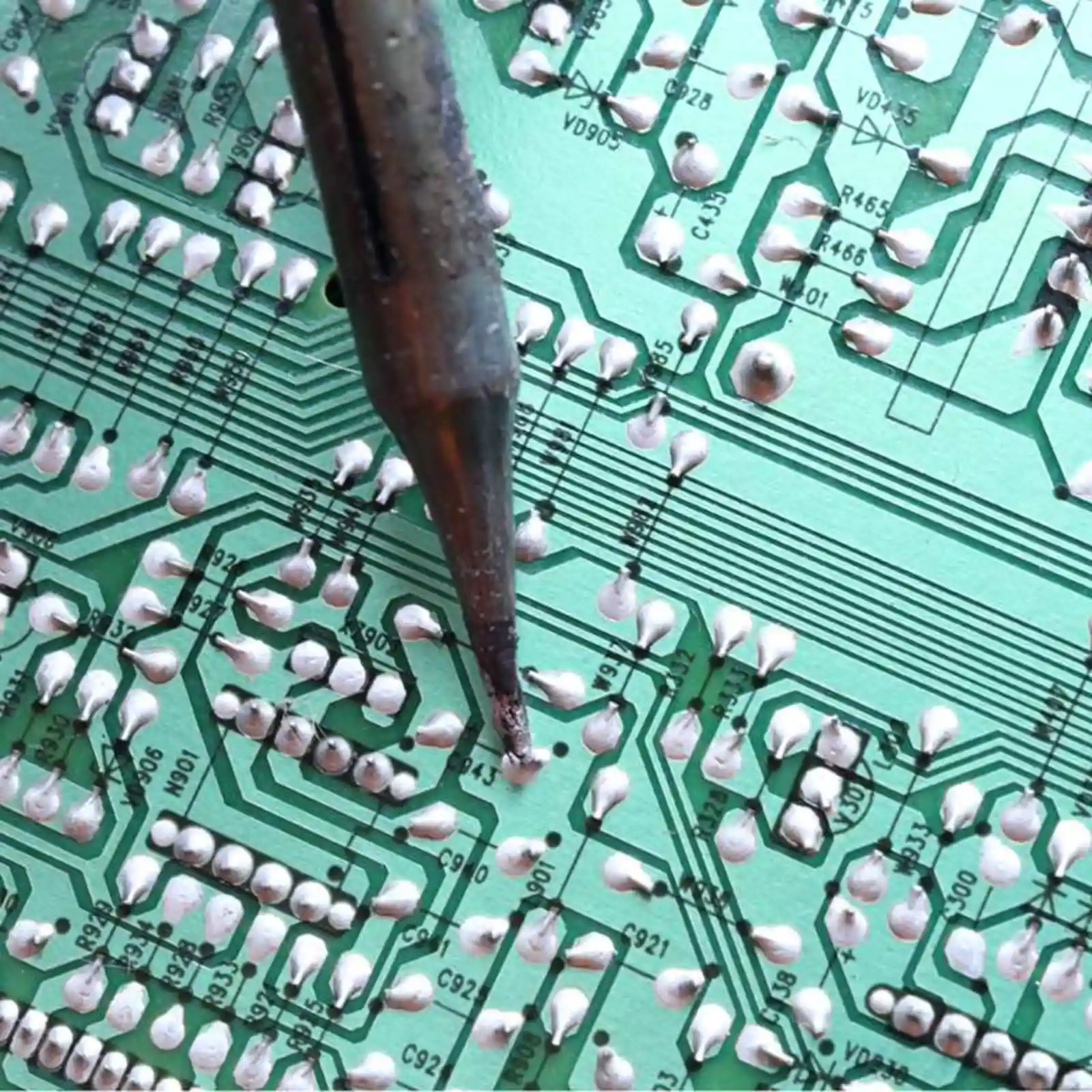

Flux and cleaning intricately intertwine, with neither being separable from the other in discussion. The assortment of fluxes and cleaning procedures wield a pivotal influence over the manufacturing yield and dependability of electronic assemblies. After the soldering process, the elimination of any corrosive residue from the surface becomes imperative.

In a world characterized by ever-evolving supply chain challenges, PCB designers are finding themselves in the position of having to craft backup plans that will ensure smooth production processes. With the unprecedented disruptions that the global market has faced in recent times, the need for alternative packaging options in the Bill of Materials (BOM) has become more apparent than ever before. Companies serving industries such as defense/military and aero - those with extremely tight controls on the materials specified for a project - will benefit greatly from the insights below!

In today's rapidly evolving electronics industry, the demand for smaller, more powerful, and complex devices is on the rise. This puts immense pressure on PCB designers to create boards that are not only high-performing but also sustainable. Achieving this balance can be challenging, as design choices that maximize performance often come at the expense of environmental friendliness. However, with concerted efforts and the right approach, it is possible to develop circuits that excel in both. In this article, we will explore some of the key factors to consider when designing sustainable PCBs.

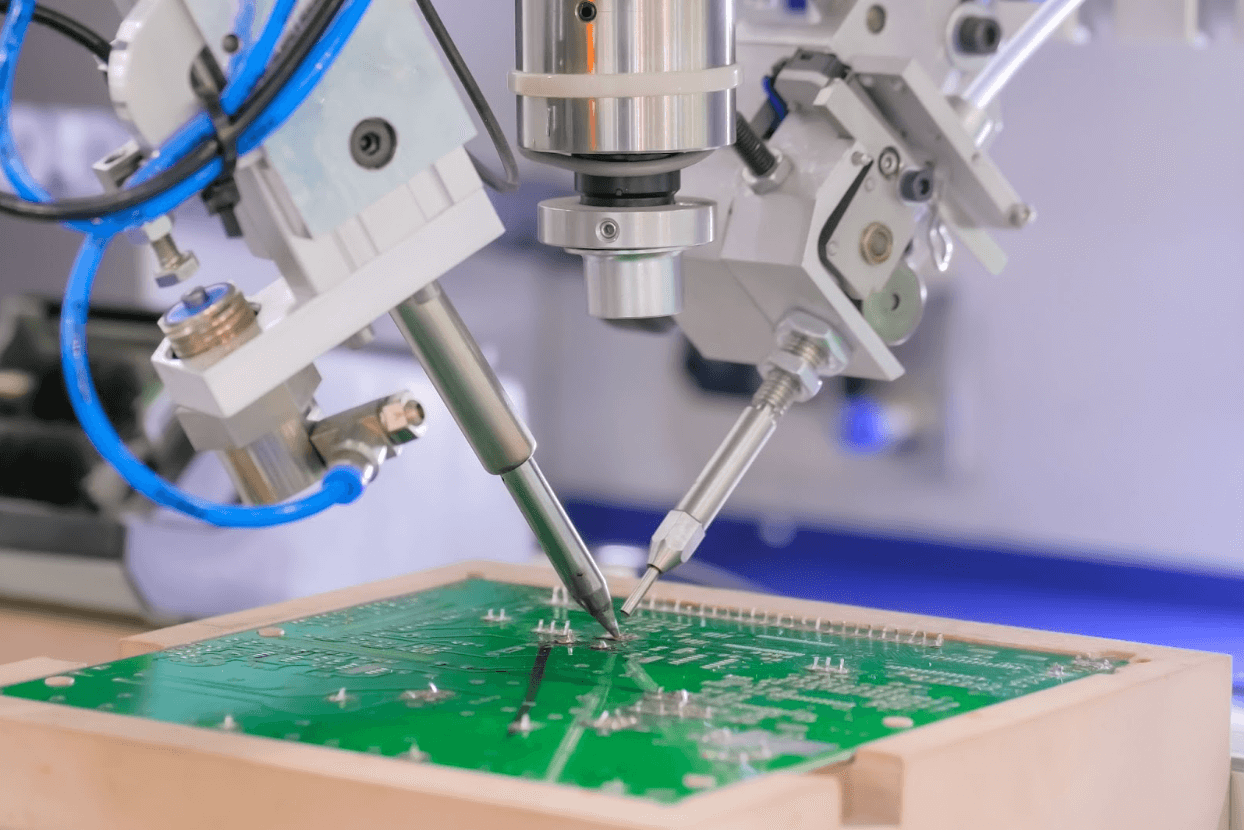

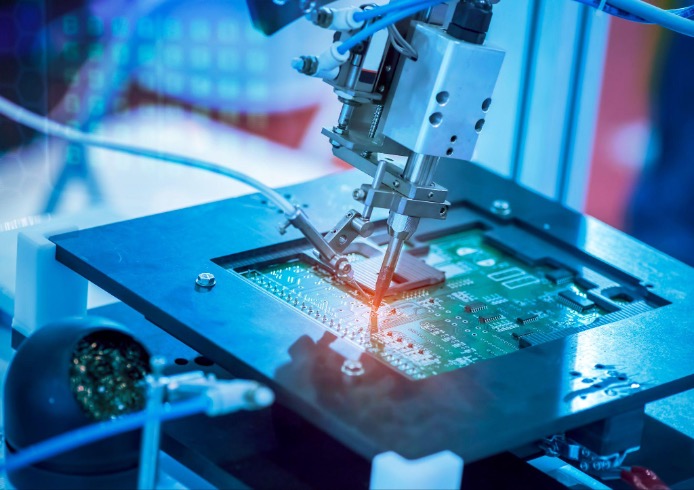

The surface mount technology (SMT) industry is a realm of perpetual evolution. Regardless of one's years of experience in SMT, there is always something new to learn. For instance, a remarkable fact emerges even after decades of SMT production: less than 10% of companies achieve a first pass yield of over 90%, leading to excessive rework for the overwhelming majority of EMS providers. Clearly, there is a pressing need for continued optimization and improvement.

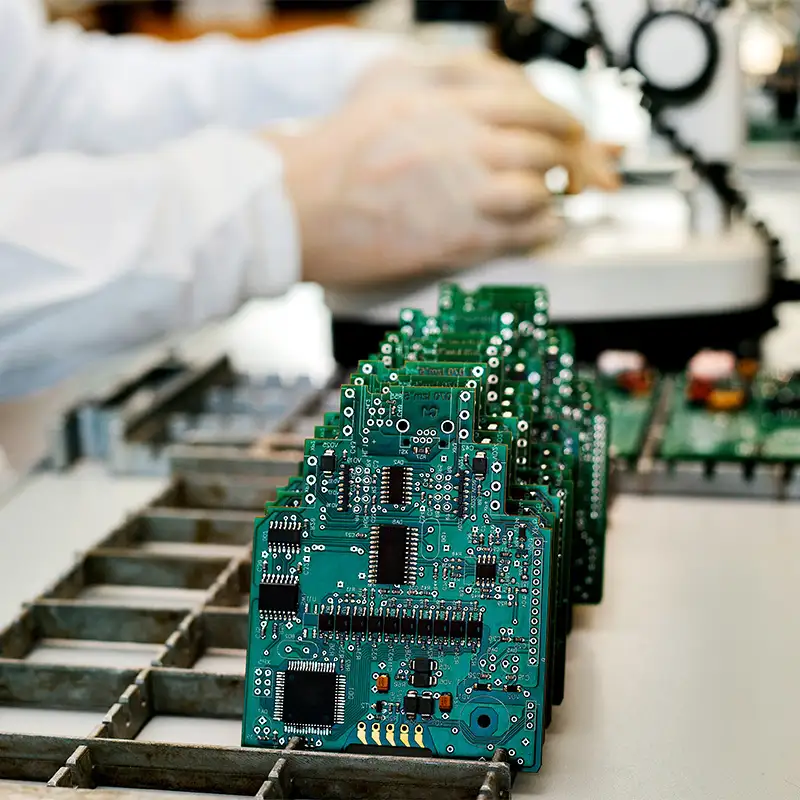

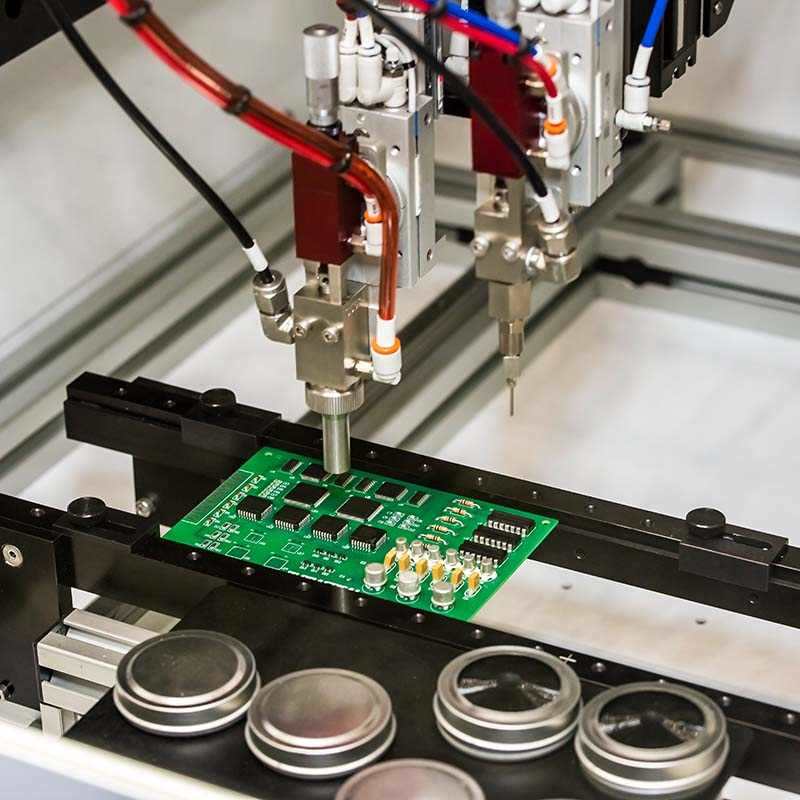

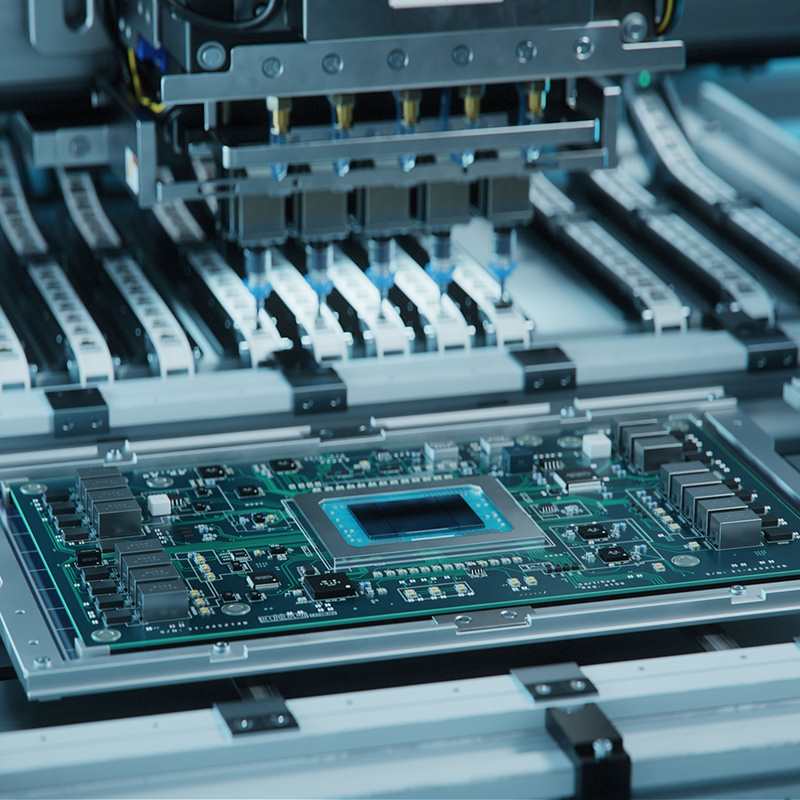

Like most industries throughout the modern manufacturing realm, today’s electronics

manufacturers are increasingly turning to automation to help their businesses remain flexible,

efficient,

and sustainable. Automated manufacturing technology offers American electronic manufacturing

service (EMS)

providers the increased capacity required to compete with their counterparts overseas. Beyond

productivity,

automation can also facilitate more consistent quality control and far more versatile product

range.

Today’s electronics manufacturing service (EMS) companies face a unique set of challenges in the

global marketplace. Supply chain issues still persist for many products, making it difficult (or

at times impossible) to procure critical materials and components. Check this article for more

on the biggest issues that today’s electronics manufacturers face.

In the fast-paced world of electronics manufacturing, time is money. To stay ahead of the

competition, companies must optimize their time investment and streamline their material

management processes. In this article, we'll share tips to help manufacturers increase

productivity, reduce waste, and achieve impeccable quality control.

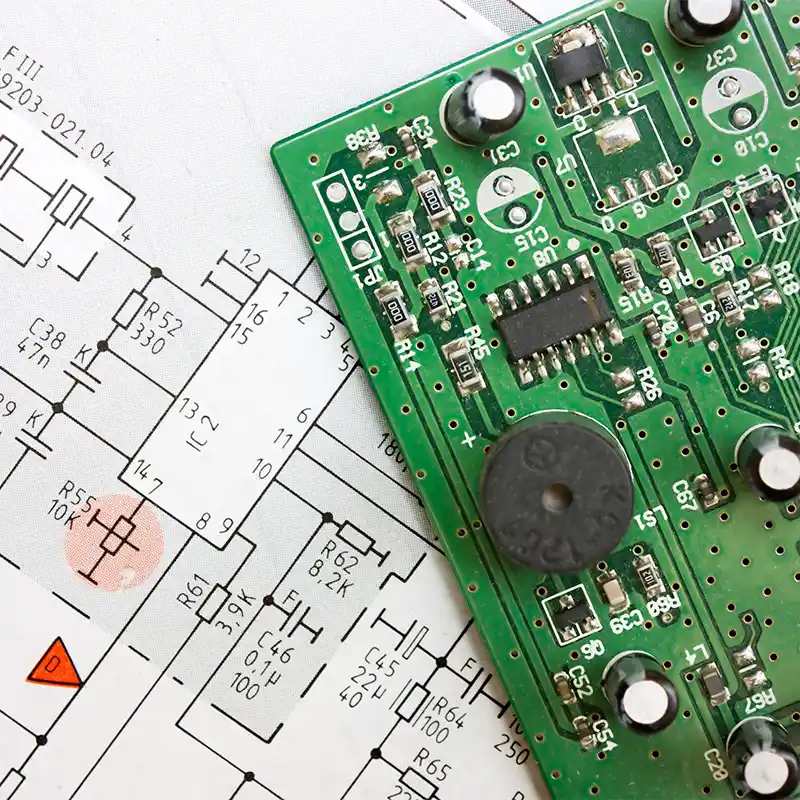

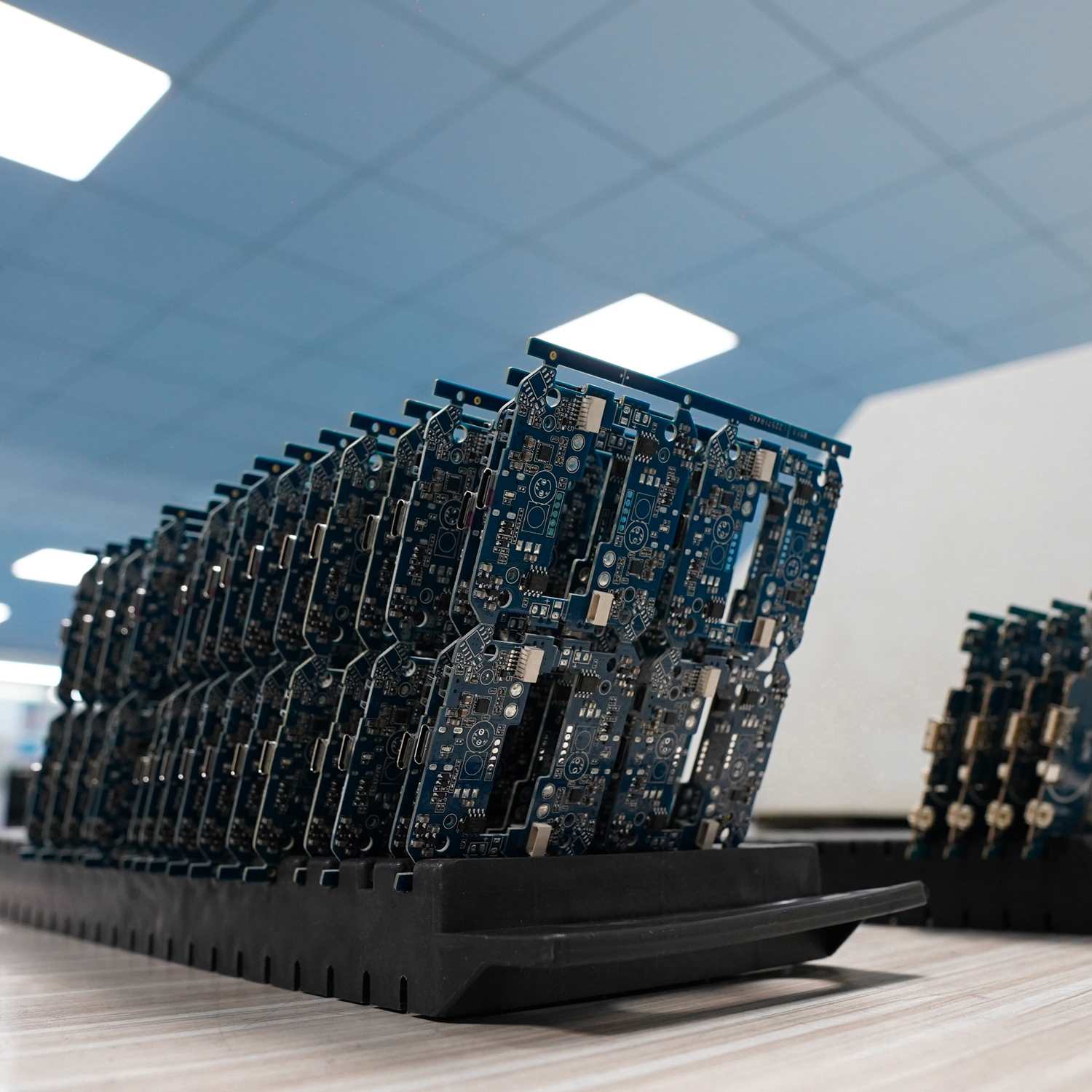

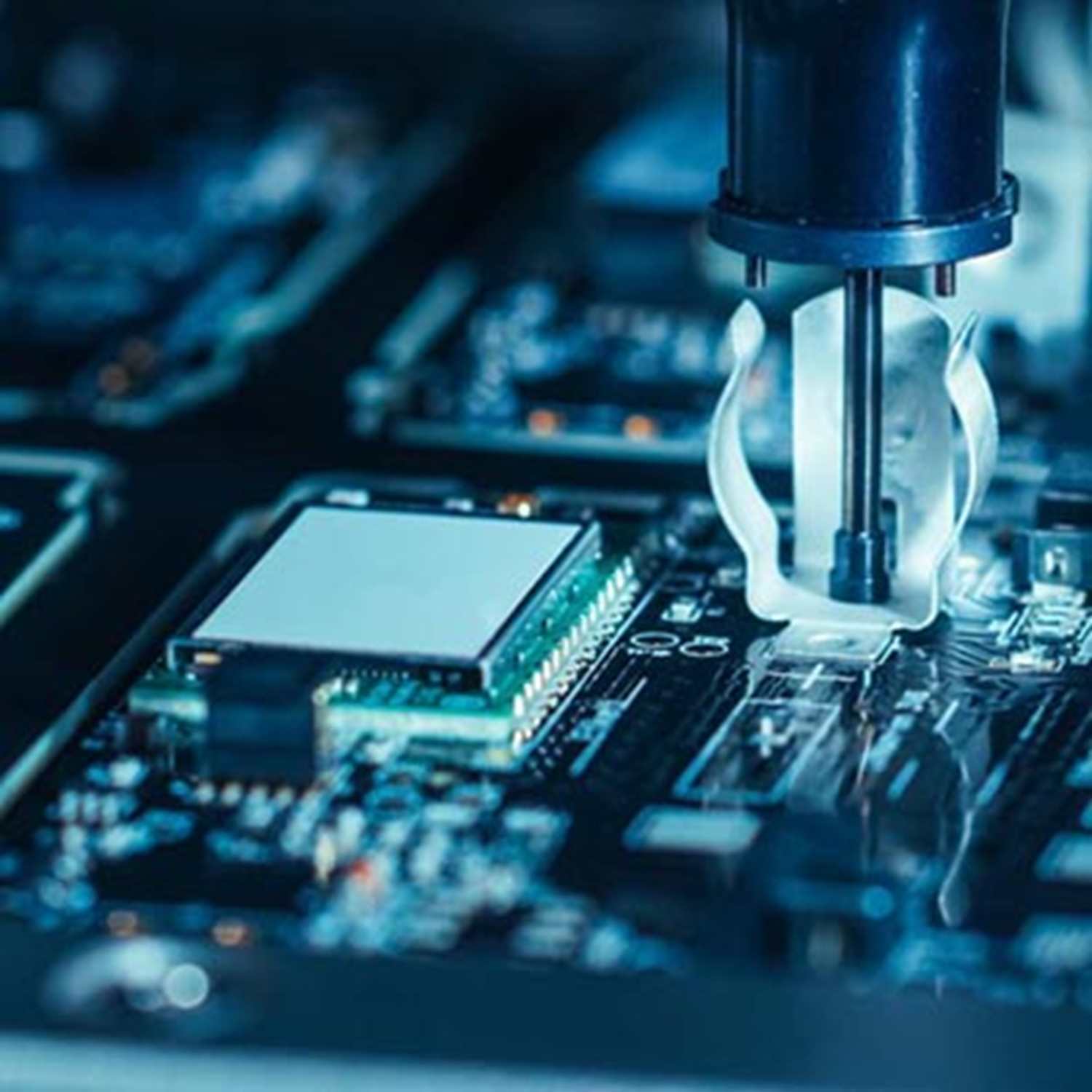

PCB assembly is a complex process that requires a high level of expertise and precision. In this

article, we explore the PCB assembly process, from the initial design to the final product, and

the steps that are taken to ensure a successful outcome.

Mastering inventory management is crucial for start-ups and small businesses to maintain

profitability and stay competitive. In this article, we explore top tips and best practices,

from consistent receiving methods to utilizing ERP systems, that can help you optimize your

inventory processes and achieve success in today's fast-paced market.

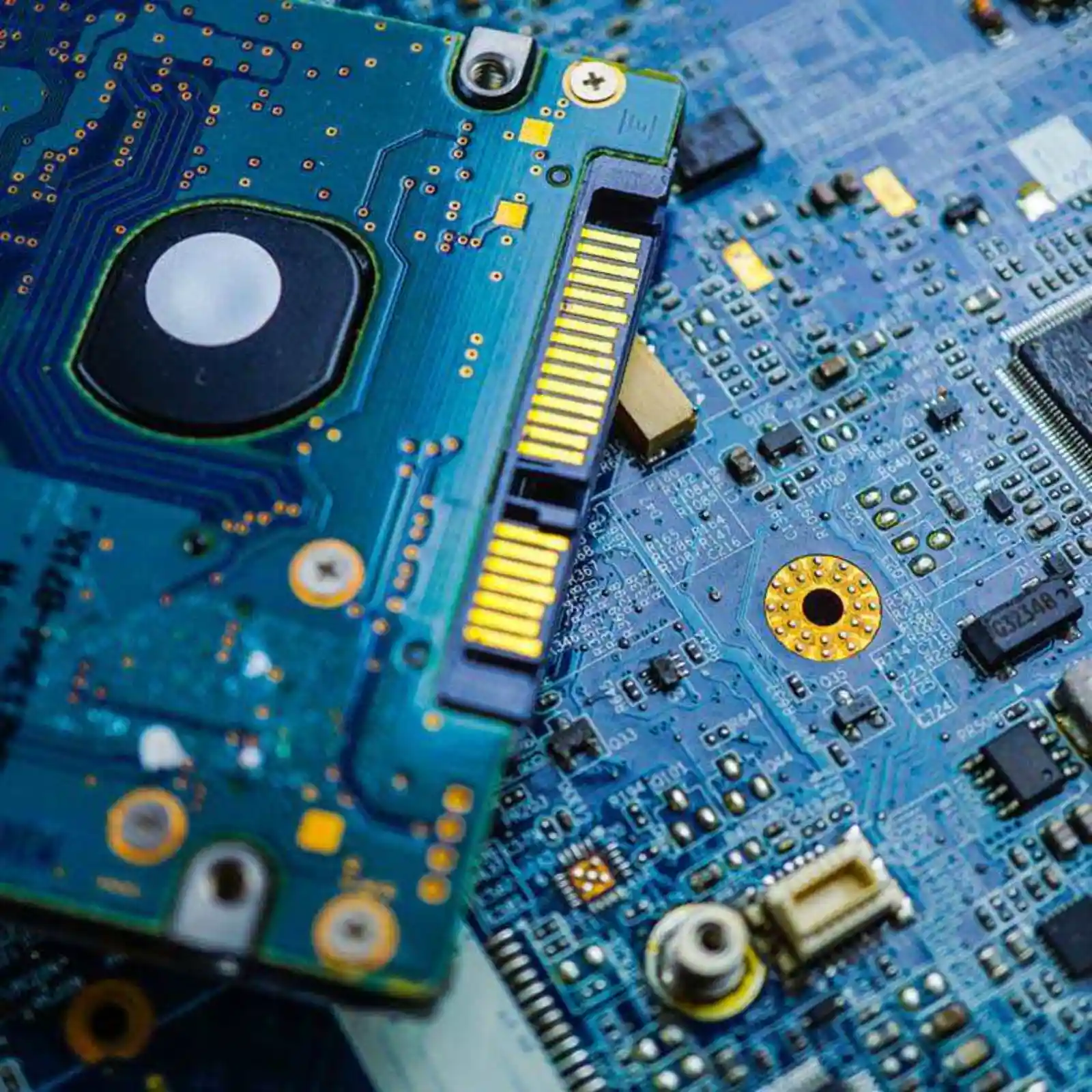

Tech is getting smaller, but growing smarter. Handheld and wearable devices require smaller

boards and increased functionality. The solution is multi-layered PCBs. These space-saving

innovations fit more circuitry and capacity in an area much smaller than traditional

single-layer and double-sided PCBs. Check out this article to learn more about the manufacturing

process for multilayer PCBs.

Technology continues to advance and shape how we experience and interact with our world,

reaching wide-ranging areas of our life related to the food we eat, the houses we live in, how

we get around, and how we communicate.

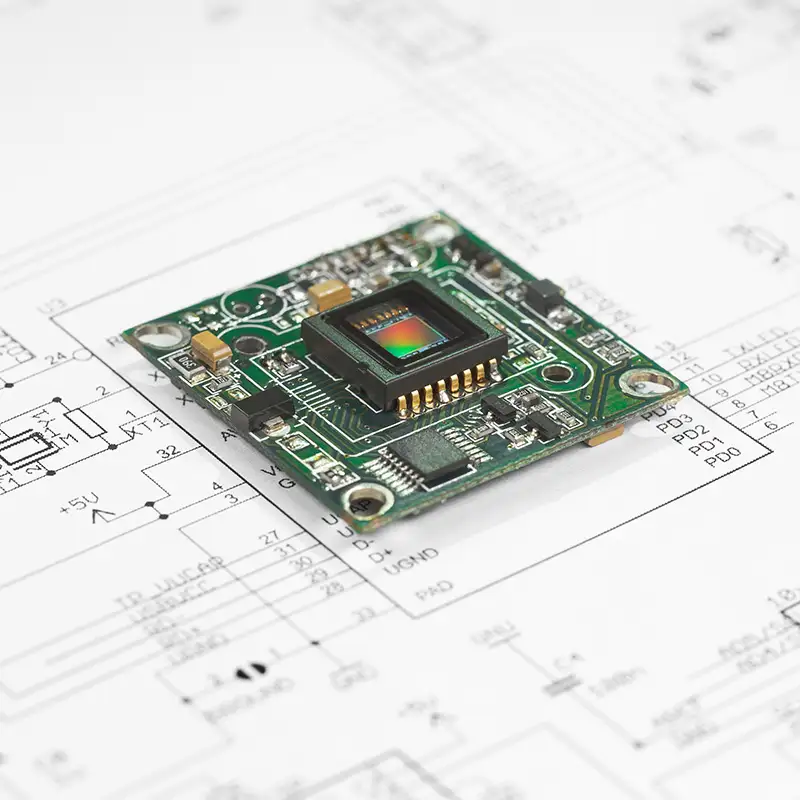

You’d never go on a trip without a map. If you did, you’d end up lost, unsure of which direction

to go and which next step to take, wasting valuable resources like time, money, and peace of

mind. When it comes to electronic assembly and manufacturing, we can help you create the

schematics your project needs to ensure increasing success.

The Covid-19 pandemic has challenged companies to optimize their PCB assembly services to better

serve clients and stay competitive. In this article, we'll explore the critical success factors

that companies are implementing to improve their services and achieve greater long-term

profitability.

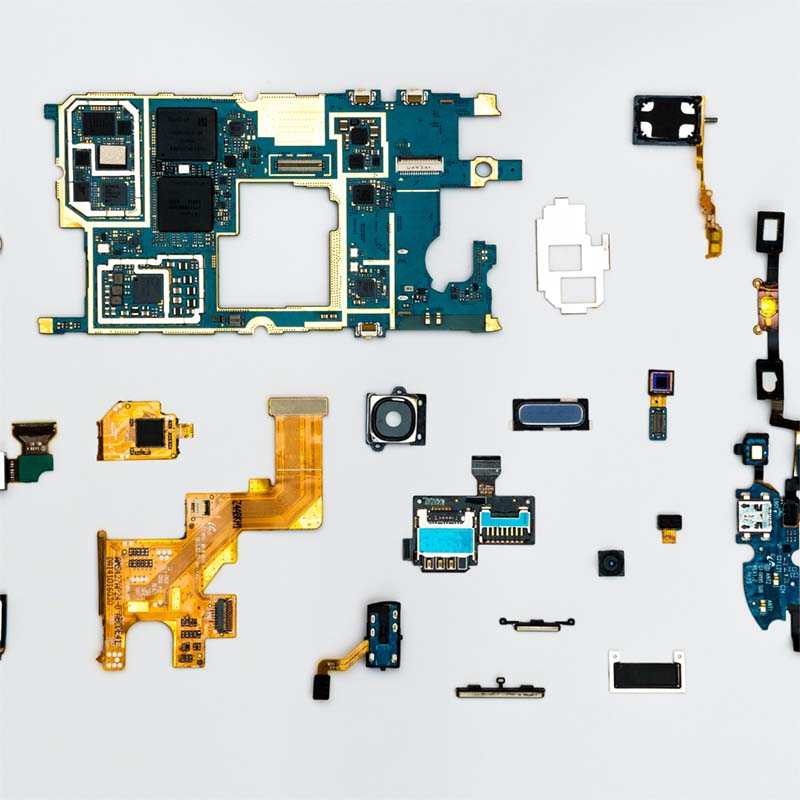

Ever wonder what makes your smart device go? While it may seem too complex to understand,

there’s actually a practical explanation. To learn more read our article: Active vs. Passive

Components.

Regardless of processes, standards, or testing, maintaining a completely foolproof method for

cleaning or determining cleanliness standards is extremely challenging. At MPL, we employ a

unique combination of engineering, sampling, and strict quality control based on years of

experience and innovation to deliver the cleanest and most reliable PCBs on the market.

This blog post provides a data-backed update on silicon wafer production and explains how recent

trends will eventually serve as great news for the semiconductor industry.

At MPL, we understand that global supply chain issues are a subject which many of our customers

have been keeping close tabs on. This blog post provides an update regarding recent

improvements, as well as the areas of industry that we are continuing to monitor.

At MPL, we believe continual improvement of PCB assembly techniques are the key to providing

customers with the highest quality final product. Discover how this dedication to quality has

impacted the way that we conduct conformal coating procedures.

From shipping to end-use, there are countless ways that moisture can be introduced to a printed

circuit board’s environment and lead to damage. Learn more about how MPL and other PCB

assemblers deal with moisture.

Have PCB assembly costs become hard to keep up with? Are large production runs creating

challenges for your business? If so, MPL has a few cost saving tips and design strategies that

can potentially save you significant amounts of time and money.

There are many ways PCB assembly companies must strategically operate in order to avoid needless

costs as the result of supply chain shortages. One of the most important areas of operation

relate to the collaborative approach of working with EMS companies, or electronics manufacturing

services companies. Good communication can often become the deciding factor as to whether an

order is delivered on time or not - today, more than ever.

Creep corrosion is a growing concern for many PCBA customers who work in high-sulfur

environments. The best strategy to avoid creep corrosion is to work with a company that

understands this type of defect thoroughly and is equipped to prevent it. This post delves into

why creep corrosion occurs and what can be done to solve this issue.

Reworking SMT connectors can be challenging, but the right assembly provider understands how to

produce high quality results every time. Read this blog post and discover how our experts carry

out a highly efficient rework process.

The newly passed CHIPS Act has provided U.S. supply bases with the resources necessary to

reinvigorate Semiconductor, "Chip", manufacturing and the electronics assembly market as a

whole. Through subsidization, tax relief and other incentives, the Government hopes to bring

American Semiconductor manufacturing stateside and decrease dependence on foreign entities. MPL

invites you to learn more about the details of the CHIPS Act and what it means for our industry.

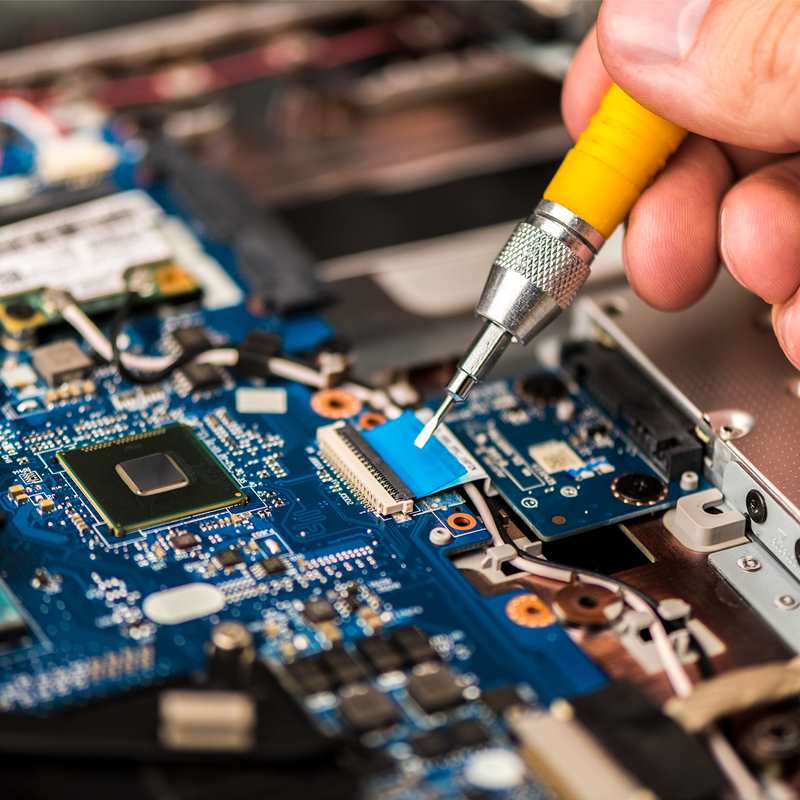

As a leading PCBA company, MPL understands the ins and outs of the assembly process, including

the most common defects that can arise during SMT assembly. We invite you to learn more about

these defects and how MPL avoids them to ensure quality in every order.

Given the many advantages of surface mount technologies, customers are curious as to how this

production strategy was initially conceived and how it has evolved over the years. This blog

post maps out SMT’s rich history and discusses how this technology continues to adapt to

evolving industry needs.

Because low volume, high mix production capabilities serve a useful purpose for many customers

with increased product line variability, it may be surprising to learn that this type of

production is less desired in the industry. Reason being, low volume/high mix production is more

"difficult" for a number of factors, but companies like MPL combat challenges using a variety of

resources which are detailed here.

Failure analysis is a method of quality assurance used across a wide variety of industries, not

limited electronics, that MPL uses to ensure every printed circuit board assembly is in perfect

functioning order. Discover what is involved during proper failure analysis procedures.

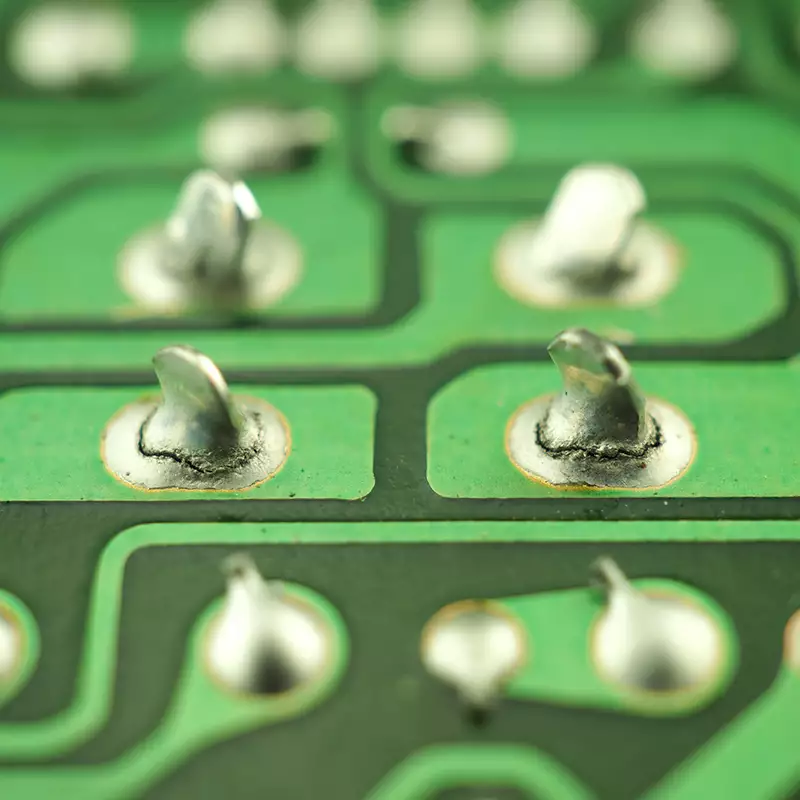

Through hole soldering defects can, at times, be the one thing preventing customers from

receiving high-quality end-product results. This is why it is crucial to understand the common

issues that occur during assembly in order to best avoid and address them.

Electronic manufacturers produce reliable PCBAs when they communicate with customers to ensure

that they fully understand their quality expectations. Explore how leading contract

manufacturers improve PCBA reliability by consistently investing in the PCB cleanliness process.

If the global “chip” shortage has impacted your business, you may be wondering why manufacturers

cannot simply stockpile these important components to avoid supply chain issues. MPL addresses

these questions by discussing the “lifespan” of semiconductor components, as well as the methods

used to increase the timeframe of usability.

At MPL, we pay close attention to the factors impacting our industry, including less talked

about issues like counterfeit PCB components. Our team eliminates risks that prove detrimental

to other PCB assembly companies by implementing strategies to avoid counterfeit parts.

Looking to mitigate quality issue risks deriving from new market trends in the PCBA industry?

MPL is knowledgeable of the most prevalent trends that have affected our industry in recent

years and shares that knowledge in our most recent blog post. Furthermore, we provide

information on how our company works to solve these potential manufacturing hazards and

continues to provide high quality products to our customers.

A manufacturer’s worst fears come to fruition when they receive their PCB assembly orders, only

to find that a defect prevents their product from functioning properly. This blog post covers

the most common PCB assembly issues, as well as the testing processes used to ensure no defect

makes it past our team unnoticed.

When supply issues threaten your business’s work flow and increase lead times for PCB assembly,

it is crucial to partner with a company that can reliably offer suggestions for alternate

components and assistance with board redesign to avoid running into LT issues again and again.

If quick turn prototype assembly is the key to full production PCB assembly, then what are the

keys to successful prototyping projects? MPL walks through three most important things needed

for a PCB assembly company to succeed at fulfilling cost-effective, high-quality prototype

assembly orders.

When choosing a PCBA company to partner with, do not make the mistake of taking into account per

unit assembly cost, only. The key to choosing the best possible PCBA company is by evaluating

possible “hidden” cost factors, which are impacted by quality, delivery, responsiveness and

communication.

Design for Manufacturability is a critical part of the overall manufacturing process and at MPL,

we have spent decades perfecting a comprehensive checklist that can help customers avoid

expensive mistakes in production. From documentation to test, explore the various factors we

consider before the full production process and how these steps improve quality and lower

manufacturing costs.

No industry is being hit like the semiconductor industry when it comes to supply chain

disruptions. Procurement teams are seeing 30, 40 and 50+ week lead times for components,

regularly, in what appears to be the “new normal”.

©2026 MPL Incorporated

Built by GORGES